Modeling Method of Multi-Grained Machining Design Intent

In the realm of modern manufacturing, the integration of advanced computational techniques and intelligent design methodologies has revolutionized the way machining processes are conceptualized, planned, and executed. The modeling of machining design intent, particularly at multiple granularity levels, has emerged as a critical area of research, addressing the complex interplay between design specifications, process planning, and operational execution in the context of Industry 4.0. Multi-grained machining design intent refers to the structured representation of design objectives and process knowledge at varying levels of detail, from high-level conceptual goals to low-level operational parameters. This approach enables the capture, reuse, and optimization of design and machining knowledge, facilitating intelligent, data-driven manufacturing processes that enhance efficiency, precision, and adaptability.

The significance of multi-grained modeling lies in its ability to bridge the semantic gap between macro-level technological strategies and micro-level process parameters, ensuring that design intent is preserved throughout the manufacturing lifecycle. By incorporating dynamic machining features, machine learning algorithms, and digital twin technologies, researchers aim to develop robust models that can adapt to the dynamic and competitive environment of modern manufacturing. This article provides a comprehensive exploration of the research on multi-grained machining design intent modeling, covering its theoretical foundations, methodologies, applications, challenges, and future directions. The discussion is grounded in recent advancements in computational modeling, finite element analysis, and artificial intelligence, with a focus on their practical implications for industry.

Historical Context and Evolution

The evolution of machining design intent modeling can be traced back to the early days of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems in the 1970s and 1980s. Initial efforts focused on static representations of machining features, which described geometric and topological characteristics of parts without capturing the dynamic interactions between design intent and process execution. These early models were limited in their ability to represent the multi-faceted nature of machining processes, particularly in complex, multi-operational environments.

With the advent of Industry 4.0, characterized by the integration of cyber-physical systems, big data, and artificial intelligence, the need for more sophisticated modeling approaches became apparent. Researchers began to explore multi-grained modeling as a means to encapsulate design intent at multiple levels of abstraction. This shift was driven by the recognition that manufacturing processes are inherently hierarchical, involving interactions between high-level design objectives, mid-level process planning, and low-level operational controls. The introduction of dynamic machining features, which evolve in response to machining conditions, marked a significant milestone in this evolution, enabling models to reflect real-time changes in process parameters and environmental factors.

Key milestones in the development of multi-grained modeling include the adoption of finite element methods (FEM) for simulating machining processes, the integration of machine learning for predictive modeling, and the emergence of digital twin technology for real-time process monitoring and optimization. These advancements have collectively contributed to a paradigm shift in machining design, moving from static, geometry-centric models to dynamic, intent-driven frameworks that prioritize adaptability and intelligence.

Theoretical Foundations

Design Intent in Machining

Design intent in machining refers to the explicit and implicit objectives that guide the creation of a machined part, encompassing functional requirements, geometric tolerances, material properties, and manufacturing constraints. In multi-grained modeling, design intent is represented at multiple levels of granularity, allowing for a hierarchical decomposition of objectives. For instance, at the macro level, design intent may include achieving a specific surface finish or dimensional accuracy, while at the micro level, it may involve optimizing cutting parameters such as feed rate or spindle speed.

The theoretical underpinning of multi-grained modeling draws from several disciplines, including mechanical engineering, computer science, and systems theory. Systems theory, in particular, provides a framework for understanding the hierarchical relationships between different levels of design intent, enabling the development of models that capture both global and local objectives. This hierarchical approach is critical for addressing the complexity of modern machining processes, which involve multiple interacting variables and constraints.

Multi-Grained Representation

Multi-grained representation involves structuring design intent and process knowledge at varying levels of detail, from coarse-grained conceptual models to fine-grained operational parameters. Coarse-grained models focus on high-level objectives, such as overall part functionality or production efficiency, while fine-grained models address specific process parameters, such as tool path trajectories or cutting forces. This multi-level approach allows for the seamless integration of design and manufacturing data, facilitating knowledge reuse and process optimization.

The concept of multi-grained representation is closely aligned with the principles of knowledge engineering, which emphasize the structured organization and retrieval of domain-specific knowledge. In the context of machining, knowledge engineering techniques are used to formalize design intent and process data, enabling the creation of reusable process models that can be adapted to different manufacturing scenarios.

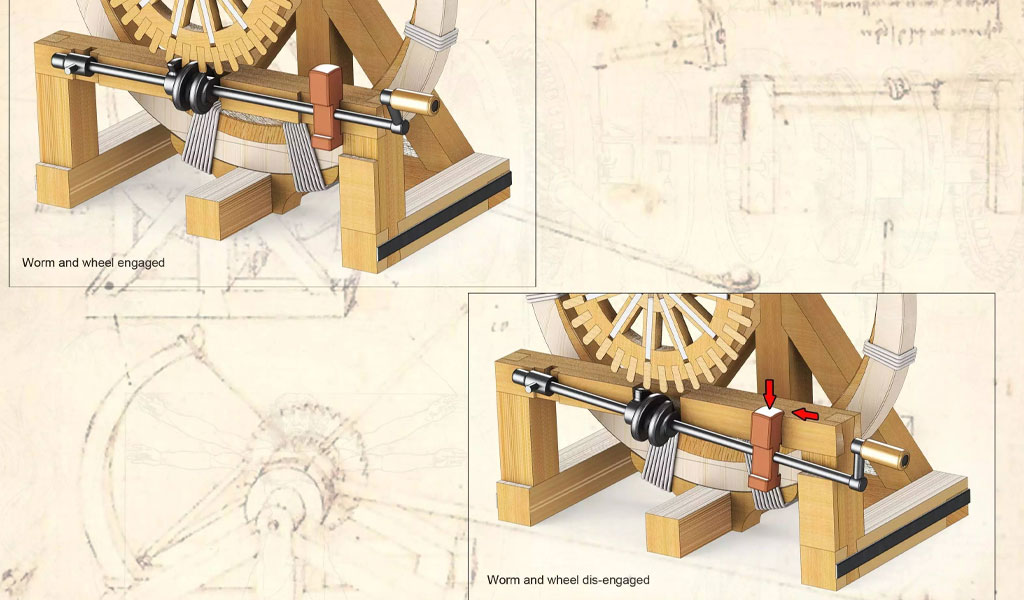

Dynamic Machining Features

Dynamic machining features are a cornerstone of multi-grained modeling, providing a mechanism for capturing the evolving nature of machining processes. Unlike static machining features, which are fixed representations of geometric entities, dynamic features adapt to changes in machining conditions, such as tool wear, material properties, or environmental factors. This adaptability is achieved through the integration of real-time data and predictive models, which allow dynamic features to reflect the current state of the machining process.

The development of dynamic machining features is supported by advances in sensor technology and data analytics, which enable the collection and processing of large volumes of process data. By incorporating this data into multi-grained models, researchers can create representations that are both accurate and responsive, enhancing the ability to predict and control machining outcomes.

Methodologies for Multi-Grained Modeling

Analytical Modeling

Analytical modeling is a traditional approach to machining process simulation, relying on mathematical equations to describe the mechanics of cutting, chip formation, and tool-workpiece interactions. In the context of multi-grained modeling, analytical models are used to predict fundamental process variables, such as cutting forces, stresses, and temperatures, at different levels of granularity. Slip-line field models and shear-zone models are examples of analytical approaches that have been adapted for multi-grained representation.

Recent advancements in analytical modeling have focused on integrating multi-grained design intent into predictive models, enabling the simulation of complex machining scenarios. For instance, updated slip-line models for serrated chip formation incorporate dynamic machining features to account for variations in cutting conditions, improving the accuracy of force and temperature predictions. However, analytical models are limited by their reliance on simplifying assumptions, which may not fully capture the complexity of industrial machining processes.

Finite Element Modeling (FEM)

Finite element modeling (FEM) has become a cornerstone of machining process simulation, offering a numerical approach to modeling complex thermo-mechanical interactions. FEM is particularly well-suited for multi-grained modeling, as it allows for the simulation of machining processes at multiple scales, from macro-level part deformation to micro-level chip formation. By discretizing the machining domain into finite elements, FEM enables the detailed analysis of stress, strain, and temperature distributions, providing insights into the impact of design intent on process outcomes.

Recent research has focused on enhancing FEM for multi-grained modeling through the integration of dynamic machining features and advanced material models. For example, studies on orthogonal machining of Inconel 718 have utilized FEM to model dynamic recrystallization and grain refinement, incorporating multi-grained design intent to predict hardness and grain size variations. The Johnson-Cook material model is commonly used in FEM simulations to describe material behavior under high strain rates and temperatures, although accurate determination of material constants remains a challenge.

Machine Learning and Artificial Intelligence

Machine learning (ML) and artificial intelligence (AI) have emerged as powerful tools for multi-grained modeling, enabling the development of data-driven predictive models that capture complex relationships between design intent and process outcomes. ML algorithms, such as neural networks and support vector machines, are used to predict machining performance metrics, such as surface roughness, tool wear, and cutting forces, based on historical and real-time process data.

In multi-grained modeling, ML techniques are employed to bridge the gap between coarse-grained and fine-grained representations, facilitating the integration of high-level design objectives with low-level operational parameters. For instance, artificial neural network (ANN) models have been developed to optimize wire electro-discharge machining (WEDM) of Inconel 718, incorporating multi-grained design intent to predict surface quality and material removal rate. Deep learning approaches, such as CGnets, have also been explored for coarse-grained modeling, learning multi-body interactions to improve the accuracy of force predictions.

Digital Twin Technology

Digital twin technology represents a paradigm shift in multi-grained modeling, enabling the creation of virtual representations of physical machining systems that evolve in real-time. A digital twin integrates multi-grained design intent with real-time sensor data, simulation models, and predictive algorithms, providing a comprehensive framework for process monitoring, optimization, and control. In the context of machine tools, digital twins are used to simulate the entire lifecycle of a tool, from design to operation, capturing dynamic interactions between design intent and process execution.

Recent advancements in digital twin modeling have focused on data-based and mechanism-data dual-driven approaches, which combine physical models with machine learning to enhance predictive accuracy. For example, digital twin models of intelligent machine tools have been developed to enable autonomous construction and updates, incorporating multi-grained design intent to optimize tool status and process performance. These models are particularly valuable in high-precision industries, such as aerospace, where the ability to predict and control machining outcomes is critical.

Applications of Multi-Grained Modeling

Conventional Machining

Conventional machining processes, such as turning, milling, and grinding, are among the primary beneficiaries of multi-grained modeling. These processes involve complex interactions between cutting tools, workpieces, and machine tools, requiring precise control of process parameters to achieve desired outcomes. Multi-grained modeling enables the simulation and optimization of conventional machining processes, capturing design intent at multiple levels to improve product quality and process efficiency.

Recent studies have demonstrated the effectiveness of multi-grained modeling in conventional machining. For instance, analytical and numerical models have been used to predict chip geometry, forces, and temperatures in orthogonal cutting, incorporating dynamic machining features to account for variations in cutting conditions. Similarly, FEM simulations of grinding processes have been employed to optimize grinding parameters, such as wheel speed and feed rate, based on multi-grained design intent.

Additive Manufacturing and Hybrid Processes

The integration of additive manufacturing (AM) with conventional machining has given rise to hybrid manufacturing processes, which combine the flexibility of AM with the precision of subtractive machining. Multi-grained modeling is particularly valuable in hybrid processes, as it enables the seamless integration of design intent across different manufacturing stages. For example, models of wire electro-discharge machining (WEDM) of additively manufactured Inconel 718 have incorporated multi-grained design intent to optimize surface finish and cutting speed, accounting for the unique microstructural characteristics of AM parts.

Composite Materials Machining

Machining of composite materials, such as carbon fiber-reinforced polymers (CFRPs) and metal matrix composites (MMCs), presents unique challenges due to their anisotropic and heterogeneous nature. Multi-grained modeling has been applied to composite machining to predict cutting forces, tool-particle interactions, and subsurface damage, incorporating design intent to optimize process parameters. For instance, finite element models of CFRP grinding have been developed to simulate grain-fiber interactions, using multi-grained representations to capture the complex mechanics of composite machining.

Industry 4.0 and Smart Manufacturing

In the context of Industry 4.0, multi-grained modeling plays a central role in enabling smart manufacturing, where intelligent systems adapt to changing conditions in real-time. Digital twin technology, supported by multi-grained models, facilitates the integration of design intent with real-time process data, enabling autonomous decision-making and process optimization. Applications in smart manufacturing include tool condition monitoring, predictive maintenance, and adaptive control, all of which rely on multi-grained representations to achieve high performance and reliability.

Comparative Analysis of Modeling Methods

To provide a comprehensive understanding of the various methodologies used in multi-grained modeling, the following table compares key approaches based on their capabilities, advantages, limitations, and applications.

|

Method |

Capabilities |

Advantages |

Limitations |

Applications |

|---|---|---|---|---|

|

Analytical Modeling |

Predicts cutting forces, stresses, and temperatures using mathematical equations |

Fast computation, suitable for real-time applications |

Relies on simplifying assumptions, limited to simple geometries |

Orthogonal cutting, chip formation analysis, process optimization |

|

Finite Element Modeling (FEM) |

Simulates complex thermo-mechanical interactions at multiple scales |

High accuracy, detailed analysis of stress/strain distributions |

Computationally intensive, requires accurate material models |

Turning, milling, grinding, composite machining, microstructure prediction |

|

Machine Learning (ML) |

Predicts performance metrics using data-driven models |

Handles complex, non-linear relationships, adaptable to new data |

Requires large datasets, lacks physical interpretability |

Surface roughness prediction, tool wear monitoring, process parameter optimization |

|

Digital Twin Technology |

Integrates real-time data with simulation models for process monitoring and control |

Real-time adaptability, comprehensive lifecycle analysis |

High implementation cost, requires robust data infrastructure |

Smart manufacturing, tool condition monitoring, predictive maintenance |

This table highlights the complementary nature of different modeling methods, each offering unique strengths that can be leveraged depending on the specific requirements of the machining process. Analytical models are ideal for rapid predictions, while FEM provides detailed insights into complex interactions. ML excels in data-driven scenarios, and digital twins offer real-time adaptability, making them suitable for Industry 4.0 applications.

Challenges in Multi-Grained Modeling

Complexity of Machining Environments

Machining processes are inherently complex, involving high deformation rates, thermo-mechanical interactions, and tribological conditions. Capturing these interactions in multi-grained models requires sophisticated representations that can account for dynamic changes in process parameters and environmental factors. The challenge is compounded by the need to integrate data from multiple sources, such as sensors, CAD/CAM systems, and historical process records, into a cohesive model.

Data Integration and Quality

Effective multi-grained modeling relies on the availability of high-quality data at multiple levels of granularity. However, data integration remains a significant challenge, as manufacturing systems often generate heterogeneous data in different formats and at varying frequencies. Ensuring data consistency, accuracy, and completeness is critical for the development of reliable models, particularly in data-driven approaches such as machine learning and digital twins.

Computational Efficiency

The computational demands of multi-grained modeling, particularly for FEM and digital twin applications, can be significant. Simulating complex machining processes at multiple scales requires substantial computational resources, which may limit the feasibility of real-time applications. Researchers are exploring hybrid approaches, such as combining analytical and numerical models, to improve computational efficiency while maintaining accuracy.

Transferability and Scalability

Many multi-grained models are developed for specific machining scenarios, limiting their transferability to other processes or materials. For example, coarse-grained models designed for protein folding simulations may not be directly applicable to different molecular systems due to variations in interaction potentials. Similarly, models developed for conventional machining may not scale effectively to hybrid or composite machining processes. Achieving transferability and scalability requires the development of generalized frameworks that can adapt to diverse manufacturing contexts.

Future Directions

Integration of Advanced AI Techniques

The integration of advanced AI techniques, such as reinforcement learning and transfer learning, holds significant promise for multi-grained modeling. These techniques can enhance the adaptability and generalization of models, enabling them to learn from diverse datasets and apply knowledge to new scenarios. For instance, transfer learning could be used to adapt models developed for conventional machining to hybrid processes, reducing the need for extensive retraining.

Development of Hybrid Modeling Frameworks

Hybrid modeling frameworks, which combine analytical, numerical, and data-driven approaches, are likely to play a central role in the future of multi-grained modeling. By leveraging the strengths of each method, hybrid frameworks can achieve a balance between accuracy, computational efficiency, and adaptability. Recent research suggests that hybrid analytical/numerical approaches are a major goal for future development, particularly for predicting industry-relevant outcomes.

Expansion of Digital Twin Applications

The expansion of digital twin applications in machining is expected to drive significant advancements in multi-grained modeling. Future digital twins will likely incorporate more sophisticated multi-grained representations, enabling real-time optimization of complex manufacturing systems. Research is needed to address challenges related to data integration, computational efficiency, and model scalability to fully realize the potential of digital twins in smart manufacturing.

Standardization and Knowledge Sharing

To facilitate the widespread adoption of multi-grained modeling, there is a need for standardization of modeling frameworks and knowledge-sharing platforms. Standardized formats for representing multi-grained design intent and process data can improve interoperability between different systems and enable the reuse of models across industries. Collaborative platforms, such as open-source repositories, can further accelerate research and development by providing access to shared datasets and modeling tools.

Conclusion

The modeling of multi-grained machining design intent represents a transformative approach to modern manufacturing, enabling the integration of design objectives and process knowledge at multiple levels of granularity. By leveraging analytical modeling, finite element methods, machine learning, and digital twin technology, researchers have developed sophisticated frameworks that enhance the precision, efficiency, and adaptability of machining processes. Despite challenges related to complexity, data integration, computational efficiency, and transferability, ongoing advancements in AI, hybrid modeling, and digital twins are paving the way for future innovations.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

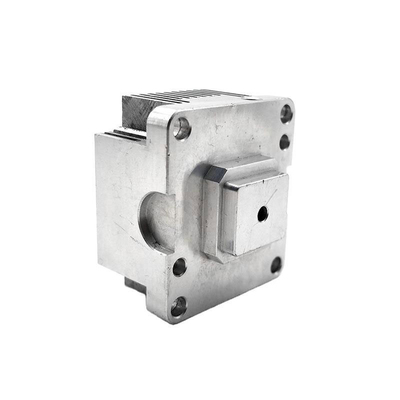

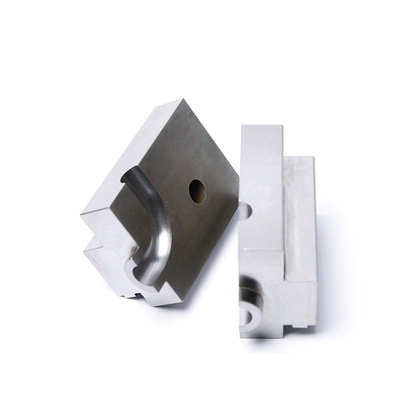

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material