A Comprehensive Guide to Different Types of Lathe Cutting Tools for Turning, Boring, Facing, Chamfering, and More Operations

Lathe machines have been a fundamental part of machining for centuries, enabling the creation of precise and intricate cylindrical components. One of the key factors that determine the success of lathe operations is the selection and utilization of cutting tools. These tools come in a wide variety of shapes, sizes, and materials, each designed for specific tasks such as turning, boring, facing, chamfering, and more. In this comprehensive guide, we will explore the world of lathe cutting tools, delving into their types, characteristics, applications, and best practices for optimal machining results. Whether you're a novice looking to learn the basics or an experienced machinist seeking to expand your knowledge, this article aims to provide valuable insights into the intricate world of lathe cutting tools.

Section 1: Turning Tools

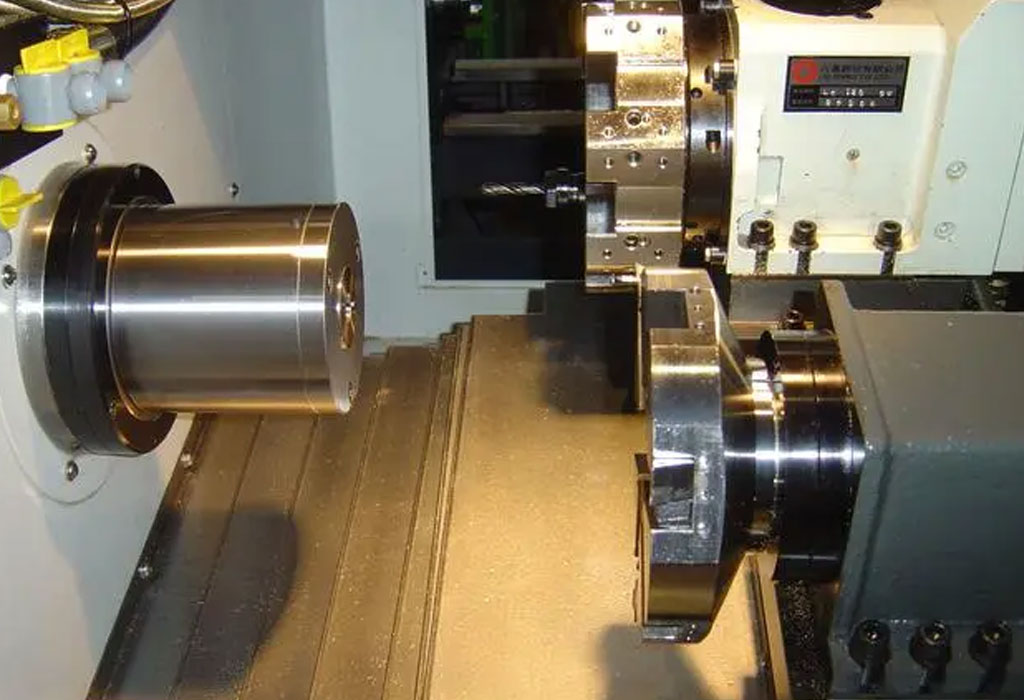

Turning operations are a cornerstone of lathe machining, playing a pivotal role in creating cylindrical components with precision and accuracy. These operations involve removing material from a workpiece by rotating it against a cutting tool, typically mounted on a spindle. Turning is fundamental in various industries, including automotive, aerospace, manufacturing, and more, making it crucial for understanding the tools used in the process. Turning tools, in the context of lathe machining, are the cutting instruments that shape and refine workpieces during turning operations. They come in a wide array of forms, materials, and geometries to suit different requirements and materials. Understanding the significance of turning tools and their various types is essential for achieving desired machining outcomes.1.2. Types of Turning Tools

Turning tools are available in several types, each designed to cater to specific machining needs. Let's explore some common categories:- 1.2.1. High-Speed Steel (HSS) Tools:High-Speed Steel (HSS) tools have been a staple in machining for decades. They are renowned for their versatility, as they can effectively cut various materials, including ferrous and non-ferrous metals, plastics, and even wood. HSS tools can maintain their hardness and cutting ability at elevated temperatures, making them suitable for high-speed turning.

- 1.2.2. Carbide Insert Tools:Carbide insert tools have gained popularity due to their exceptional hardness and wear resistance. These tools feature replaceable carbide inserts that provide sharp cutting edges and extended tool life. They are excellent for turning hard materials like stainless steel, machining cast iron, and exotic alloys. Carbide insert tools are commonly used in both roughing and finishing operations.

- 1.2.3. Diamond Tools:Diamond turning tools use synthetic diamond as the cutting material. Diamonds are renowned for their hardness, which allows for precision machining of extremely hard materials like ceramics and glass. Diamond tools are ideal for applications that require superior surface finish and dimensional accuracy.

- 1.2.4. Cermet Tools:Cermet tools are a hybrid of ceramics and metals, offering a balance between hardness and toughness. They are well-suited for machining high-temperature alloys and hardened steels. Cermet tools excel in high-speed machining applications, where they can withstand elevated temperatures and maintain their cutting performance.

- 1.2.5. Cubic Boron Nitride (CBN) Tools:Cubic Boron Nitride (CBN) tools are among the hardest cutting tools available, second only to diamond. They are ideal for machining hardened steels and superalloys. CBN tools offer exceptional wear resistance, making them suitable for continuous and interrupted cuts in challenging materials.

1.3. Choosing the Right Turning Tool

Selecting the appropriate turning tool is a critical decision that influences the success of a machining operation. Here are key factors to consider when choosing a turning tool:- 1.3.1. Material Compatibility:The workpiece material is a crucial factor in tool selection. Different materials have varying hardness, abrasiveness, and thermal conductivity. Ensure that the chosen tool is compatible with the workpiece material to prevent premature wear or tool failure.

- 1.3.2. Tool Geometry:The geometry of the tool, including its shape, rake angle, and clearance angles, significantly impacts cutting performance. Consider the specific requirements of the turning operation, such as roughing or finishing, and select a tool with appropriate geometry to optimize results.

1.4. Tips for Successful Turning

Achieving successful turning operations requires attention to detail and precision. Here are some essential tips for maximizing the effectiveness of turning tools:- 1.4.1. Proper Tool Setup and Alignment:Ensure that the tool is securely mounted and aligned correctly on the lathe's tool post. Any misalignment can lead to poor surface finish, increased tool wear, and reduced accuracy.

- 1.4.2. Machining Parameters and Surface Finish Considerations:Adjust cutting parameters such as cutting speed, feed rate, and depth of cut according to the workpiece material and tool type. Carefully control these parameters to achieve the desired surface finish, dimensional accuracy, and chip evacuation.

Section 2: Boring Tools

2.1. Introduction to Boring Tools

Boring operations are integral to machining processes, allowing for the precise enlargement or refinement of existing holes in workpieces. Whether it's creating accurately sized holes in engine blocks or achieving tight tolerances in cylindrical components, boring tools are indispensable in various industries. In this section, we will delve into the world of boring tools used in lathe machining. Boring tools, as the name suggests, are designed to bore holes with high precision. They are particularly useful when standard drilling methods are inadequate or when the hole needs to be accurately aligned with an existing feature. Understanding the importance of boring operations and gaining insights into the types of boring tools available are vital for achieving accurate machining results.2.2. Types of Boring Tools

Boring tools encompass a range of specialized instruments, each designed for specific applications. Let's explore some common categories of boring tools:- 2.2.1. Boring Bars:Boring bars are versatile and widely used in lathe machining. These slender, elongated tools are capable of reaching deep within workpieces to bore holes accurately. Boring bars can accommodate various insert types, making them suitable for both roughing and finishing operations.

- 2.2.2. Boring Heads:Boring heads offer greater flexibility in terms of adjusting the bore's diameter. They consist of a body that houses the cutting tool and a mechanism for incremental adjustments. This allows machinists to precisely control the bore's size during the machining process.

- 2.2.3. Roughing and Finishing Boring Tools:In some cases, the boring operation is divided into two stages: roughing and finishing. Roughing boring tools are designed for material removal at higher feed rates, while finishing boring tools provide the required accuracy and surface finish. Using a combination of these tools allows for efficient and precise boring operations.

2.3. Selecting the Right Boring Tool

Choosing the appropriate boring tool is crucial for achieving successful machining outcomes. Several factors influence the selection of a boring tool:2.3.1. Factors Influencing Boring Tool Choice

- Workpiece Material: The material being machined greatly affects tool selection. Harder materials may require specialized tooling with carbide inserts, while softer materials may be effectively machined with high-speed steel (HSS) tools.

- Hole Size and Tolerance: The desired bore size and tightness of tolerances dictate the choice of boring tool. Boring heads are often preferred when precise control over bore diameter is necessary.

- Depth of Bore: The depth of the hole influences the choice of tool, as longer bores may require boring bars with extended reach.

- Machining Conditions: Consider the machining environment, such as whether it is a CNC lathe or manual lathe, as well as the available cutting fluid and coolant systems.

2.3.2. Material Removal Rates and Tool Adjustments

To optimize boring operations, it's essential to set the correct cutting parameters, including cutting speed, feed rate, and depth of cut. Adjustments to these parameters should be made based on the workpiece material and the chosen boring tool. Properly balancing material removal rates with tool adjustments ensures efficient machining without compromising accuracy.2.4. Best Practices for Effective Boring

Achieving precision and maintaining tight tolerances in boring operations require careful attention to best practices. Here are some essential tips:- 2.4.1. Tool Setup and Workpiece Clamping:Ensure the boring tool is securely mounted and aligned with the workpiece. Proper tool setup minimizes vibrations and enhances cutting stability. Secure workpiece clamping is equally critical to prevent movement during the machining process.

- 2.4.2. Achieving Tight Tolerances and Surface Finishes:To achieve tight tolerances, make incremental adjustments to the boring tool while monitoring the bore's size with precision measuring instruments. Consistently check and maintain the cutting edge's sharpness to ensure quality surface finishes and dimensional accuracy.

Section 3: Facing Tools

3.1. Introduction to Facing Tools

Facing operations in lathe machining are vital for creating flat and smooth surfaces on the ends of cylindrical workpieces. Whether it's squaring up the ends of a shaft or ensuring a precise mating surface for components, facing is a common and crucial machining process. In this section, we will explore the role of facing operations and delve into the world of facing tools used in lathe machining. Facing tools, as their name implies, are specialized tools designed to perform facing operations efficiently. They enable machinists to remove material evenly from the workpiece's end, resulting in a flat and smooth surface. Understanding the significance of facing operations and gaining insights into the types of facing tools available are essential for achieving accurate and aesthetically pleasing machining results.3.2. Types of Facing Tools

Facing tools come in various forms, each tailored to specific facing requirements. Let's explore some common categories of facing tools:- 3.2.1. Facing Mills:Facing mills are cutting tools designed for high-speed facing operations. They typically feature multiple cutting edges or inserts, allowing for efficient material removal. Facing mills are versatile and suitable for various workpiece materials, including metals and plastics.

- 3.2.2. Face Grooving Tools:Face grooving tools are specialized for creating grooves or recesses on the face of a workpiece. These tools can be used for applications such as O-ring grooves or decorative machining. Face grooving tools are available in various geometries to accommodate specific groove profiles.

- 3.2.3. Boring Heads for Facing:Boring heads, as mentioned in the previous section, can also be used for facing operations when precise control over the finished surface is necessary. They allow for incremental adjustments to the depth of cut, ensuring accurate facing results.

3.3. Choosing the Right Facing Tool

Selecting the appropriate facing tool is crucial for achieving successful facing operations. Several factors influence the choice of a facing tool: 3.3.1. Workpiece Geometry and Material Considerations:Consider the shape and size of the workpiece, as well as its material properties. Different facing tools may be more suitable for flat, cylindrical, or irregularly shaped workpieces. Additionally, some materials may require specific tool materials or coatings to achieve optimal results. 3.3.2. Surface Finish Requirements and Tool Selection:The desired surface finish plays a significant role in tool selection. For high-quality surface finishes, tools with sharp cutting edges and the ability to make fine adjustments are preferred. Boring heads, for example, offer precise control over surface finish due to their incremental adjustments.3.4. Key Techniques for Successful Facing

Achieving success in facing operations requires attention to detail and precision. Here are some essential techniques for effective facing:- 3.4.1. Tool Positioning and Alignment:Properly position and align the facing tool with the workpiece to ensure even material removal and a flat, smooth surface. Misalignment can lead to surface irregularities and poor results.

- 3.4.2. Facing Across Various Materials and Workpiece Shapes:When facing different materials, adjust cutting parameters such as cutting speed, feed rate, and depth of cut accordingly. Be aware of the workpiece shape and consider whether the chosen tool is suitable for the specific geometry, especially when facing irregularly shaped components.

Section 4: Chamfering and Thread Cutting Tools

4.1. Introduction to Chamfering and Thread Cutting

Chamfering and thread cutting are essential machining processes that serve critical roles in various industries. Chamfering involves beveling the edges of holes, edges, or workpiece surfaces, improving their durability, aesthetics, and safety. Thread cutting is the process of creating screw threads on cylindrical workpieces, enabling the assembly of components or providing a means of fastening. In this section, we will explore the importance of chamfering and thread cutting in lathe machining and introduce the tools used for these operations. Chamfering and thread cutting tools are specialized instruments designed to perform these tasks with precision and efficiency. Understanding their significance and the types of tools available is vital for achieving desired machining outcomes.4.2. Types of Chamfering and Thread Cutting Tools

Chamfering and thread cutting tools encompass various categories, each tailored to specific machining needs. Let's delve into some common types of these tools:- 4.2.1. Chamfering Tools:Chamfering tools, also known as chamfer mills or countersinks, are designed to create beveled edges on workpieces. They come in various shapes and sizes, allowing machinists to chamfer holes, edges, or surfaces. Chamfering tools enhance the workpiece's aesthetics and functionality, reduce sharp edges, and improve assembly.

- 4.2.2. Thread Cutting Tools:Thread cutting tools are essential for creating screw threads on cylindrical workpieces. They come in different forms, including taps for internal threads and dies for external threads. Thread cutting tools are available for various thread types and pitches, making them versatile for different applications.

- 4.2.3. Thread Chasing Tools:Thread chasing tools, often referred to as thread chasers, are used for repairing or restoring damaged threads on workpieces. They are typically used when the original threads are worn or damaged, ensuring a proper fit for threaded components. Thread chasing tools come in various designs to match specific thread profiles and sizes.

- 4.3. Selecting the Right Tool for Chamfering and Thread Cutting

- 4.3.1. Angle and Size Considerations:For chamfering tools, the angle of the desired chamfer and the workpiece size determine the choice of tool. Different angles serve different purposes, such as 45-degree chamfers for general use or 90-degree chamfers for creating right angles.

- 4.3.2. Thread Types and Pitch Selection:When selecting thread cutting tools, consider the thread type (e.g., metric or unified) and the required thread pitch. Matching the tool to the specific thread type ensures proper thread profiles and accurate thread fits.

4.4. Precision Techniques for Chamfering and Thread Cutting

To achieve precision in chamfering and thread cutting, it's essential to follow best practices and techniques. Here are some key considerations:- 4.4.1. Proper Tool Setup and Alignment:Ensure that the chamfering or thread cutting tool is securely mounted and aligned with the workpiece. Misalignment can lead to inaccuracies and poor results. Additionally, maintain proper tool clearances and overhang to avoid tool interference.

- 4.4.2. Achieving Accurate Thread Profiles and Chamfer Angles:For thread cutting, monitor the thread depth, pitch, and profile carefully. Use precision measuring instruments to confirm that the threads meet the desired specifications. When chamfering, verify the chamfer angle and dimensions using appropriate measuring tools to achieve the desired finish and functionality.

Section 5: Grooving and Parting Tools

5.1. Introduction to Grooving and Parting Tools

Grooving and parting operations are fundamental to lathe machining, serving critical roles in the creation of precise components. Grooving involves cutting recesses or channels into the workpiece, often for purposes such as accommodating O-rings, retaining rings, or decorative features. Parting, on the other hand, is the process of cutting a workpiece into separate pieces or removing unwanted sections. In this section, we will explore the significance of grooving and parting operations and introduce the tools used for these tasks in lathe machining. Grooving and parting tools are specialized instruments designed to perform these operations efficiently. Understanding their importance and gaining insights into the types of tools available is vital for achieving accurate machining results.5.2. Types of Grooving and Parting Tools

Grooving and parting tools encompass various categories, each tailored to specific machining needs. Let's delve into some common types of these tools:- 5.2.1. Parting Tools:Parting tools, also known as cut-off tools, are specifically designed for separating a workpiece into two or more pieces. They feature a sharp cutting edge and are available in various shapes and sizes. Parting tools are used for applications such as cutting off a section of a rod or creating distinct components from a single workpiece.

- 5.2.2. Grooving Tools:Grooving tools are used to create channels, recesses, or grooves on the surface of a workpiece. These tools come in various geometries to accommodate specific groove profiles. Grooving tools are versatile and can be used for applications such as creating keyways, decorative patterns, or retaining features.

- 5.2.3. Threading and Cut-off Inserts:Some lathe tooling systems use threading and cut-off inserts that can serve both threading and parting functions. These inserts are designed to produce threads with precision and to cut off workpieces cleanly. They are available in different sizes and thread profiles to match specific requirements.

5.3. Choosing the Right Tool for Grooving and Parting

Selecting the appropriate grooving or parting tool is crucial for achieving successful machining outcomes. Several factors influence tool selection:- 5.3.1. Width, Depth, and Material Considerations:Consider the required groove width and depth when selecting grooving tools. Additionally, the workpiece material influences the choice of tool material and coating, as harder materials may require specialized tooling for efficient cutting.

- 5.3.2. Tool Geometry and Clearance Angles:The geometry of the tool, including the rake angle, clearance angles, and cutting edge geometry, plays a significant role in tool selection. Proper tool geometry ensures efficient chip evacuation, reduced cutting forces, and extended tool life.

5.4. Effective Techniques for Grooving and Parting

Achieving success in grooving and parting operations requires careful consideration of techniques and best practices. Here are key considerations:- 5.4.1. Workpiece Clamping and Tool Positioning:Proper workpiece clamping is essential to prevent vibration and ensure the workpiece remains securely in place during grooving or parting. Accurate tool positioning is equally critical to achieve clean and precise results.

- 5.4.2. Achieving Clean Parting and Grooving Results:Maintain appropriate cutting parameters, such as cutting speed, feed rate, and depth of cut, to ensure efficient chip evacuation and minimal tool wear. Verify that the tool's cutting edge is sharp, and employ proper tool setup to achieve clean and accurate grooves or parting lines.

Conclusion

In this comprehensive guide, we've explored a wide range of lathe cutting tools used for various operations, including turning, boring, facing, chamfering, thread cutting, grooving, and parting. These tools play a pivotal role in the world of lathe machining, allowing machinists to create precise and intricate components across diverse industries. Each section of this guide provided valuable insights into the significance of specific machining operations and introduced the types of cutting tools commonly employed. We discussed the factors influencing tool selection, the importance of material compatibility, and the role of tool geometry and cutting parameters in achieving optimal results. Throughout this article, we emphasized the importance of precision, proper tool setup, alignment, and adherence to best practices for successful lathe machining. Whether you're a novice looking to learn the basics or an experienced machinist seeking to expand your knowledge, the information presented here serves as a valuable resource to reference and refine your machining skills. As technology continues to advance, the world of lathe cutting tools remains dynamic and ever-evolving, offering new possibilities for innovation and precision in manufacturing. Whether you're turning, boring, facing, chamfering, threading, grooving, or parting, the knowledge imparted in this guide equips you with the fundamentals needed to excel in lathe machining. Remember that the choice of the right cutting tool and the mastery of precision techniques are often the keys to success in lathe machining. Continuously honing your skills, staying up-to-date with tooling advancements, and embracing the art and science of lathe machining will undoubtedly lead to the creation of exceptional components with ease and consistency. As you embark on your journey in lathe machining or seek to enhance your existing skills, may this comprehensive guide serve as a valuable reference and source of inspiration, enabling you to unlock the full potential of your lathe machine and achieve remarkable results in your machining endeavors.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

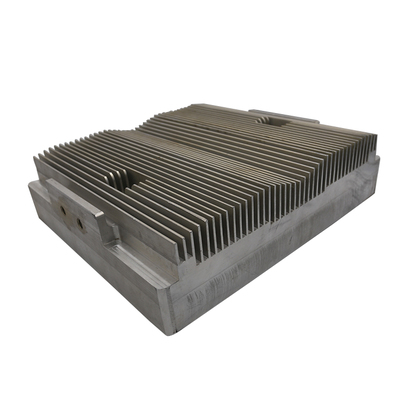

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material