What Is 3+2 Axis CNC Machining

With the continuous development of the manufacturing industry, 3+2 axis CNC machining has gradually become an efficient and high-precision machining method. This article will introduce the principle, advantages and application fields of 3+2 axis CNC machining in detail, and take you to appreciate the charm of this advanced manufacturing process!

The Define Of 3+2 Axis CNC Machining

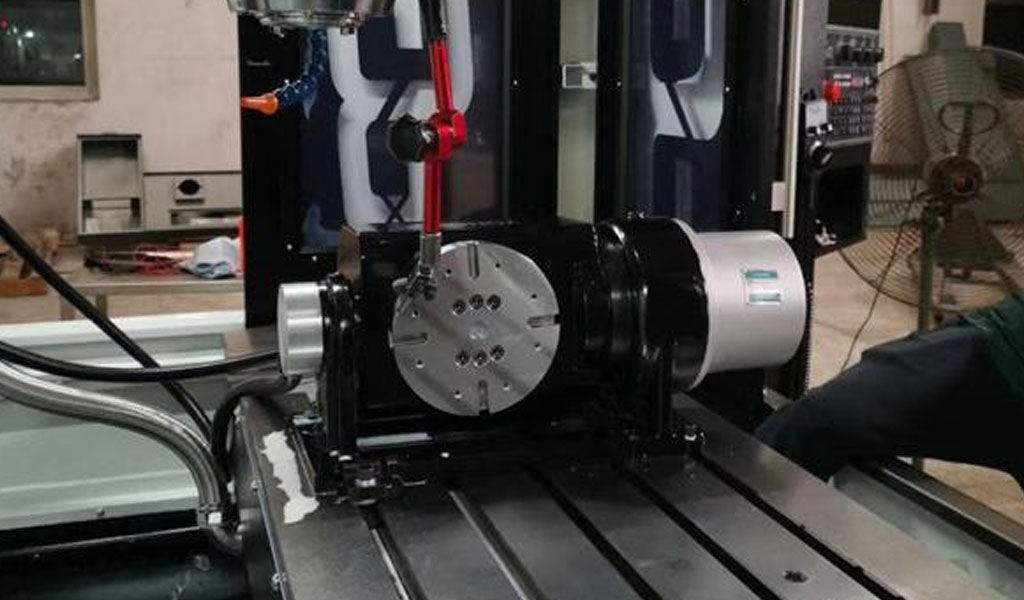

3+2-axis CNC machining, also known as positioning five-axis CNC machining, is a method in which the cutting tool is fixed at an inclined position, and then processed by the feed axes X, Y, and Z. To put it simply, the tool is first adjusted to the required angle through the two rotary axes, and then processed by the feed axis.

The advantage of this processing method is that it can realize efficient and high-precision processing of workpieces. By cutting in multiple directions, the machining time can be shortened and the machining efficiency can be improved. At the same time, by precisely controlling the angle and position of the tool, more precise cutting can be achieved and the quality of the workpiece can be improved.

The Advantages Of 3+2 Axis CNC Machining

- High efficiency: 3+2 axis CNC machining can cut in multiple directions, which shortens the processing time and improves the processing efficiency.

- High precision: By precisely controlling the angle and position of the tool, more precise cutting can be achieved and the quality of the workpiece can be improved.

- Strong adaptability: 3+2 axis CNC machining can handle various complex shapes and contours, effectively improving the adaptability and flexibility of machining.

- Reduce labor intensity: 3+2 axis CNC machining with automatic control can reduce manual operation and labor intensity.

- Reduce scrap rate: By precisely controlling the angle and position of the cutter, the generation of scrap can be reduced and the cost can be reduced.

The Application Of 3+2 Axis CNC Machining

3+2 Axis CNC Machining For Aerospace

In the aerospace field, 3+2 axis CNC machining services is widely used in the manufacture of various parts. For example, a turbine engine is a component that requires high-precision and high-efficiency manufacturing, and its blades and casings require precise geometry and high-quality surface finishing. By adopting 3+2-axis CNC machining, efficient and high-precision cutting of turbine engine blades and casings can be realized, and manufacturing quality and efficiency can be improved. In addition, in the aerospace field, many other components also require high-precision and high-efficiency manufacturing requirements. For example, aviation propellers, avionics, and aviation seats all require complex geometries and high-quality surface processing. By adopting 3+2-axis CNC machining, efficient and high-precision cutting of these parts can be realized, and the manufacturing quality and efficiency can be improved.

3+2 Axis CNC Machining For Energy

In the field of energy, 3+2 axis CNC machining is also widely used in the manufacture of various equipment. For example, the blades of wind power generators, nuclear power generators and other equipment usually have complex three-dimensional contours and high-quality surface processing requirements. By adopting 3+2-axis CNC machining, efficient and high-precision cutting of these blades can be realized, and the manufacturing quality and efficiency can be improved. In addition, some other equipment in the energy field also requires 3+2 axis CNC machining to achieve high-efficiency and high-precision manufacturing requirements. For example, the drill bits of oil drilling platforms require precise geometry and high-quality surface processing requirements. By adopting 3+2 axis CNC machining, efficient and high-precision cutting of drill bits can be achieved to improve manufacturing quality and efficiency.

3+2 Axis CNC Machining For Automobile

In the field of automobile manufacturing, 3+2 axis CNC machining is widely used in the manufacture of various parts. Components such as engines and gearboxes often require complex geometries and high-quality surface processing requirements. Through the use of 3+2 axis CNC machining, efficient and high-precision cutting of these parts can be achieved to improve manufacturing quality and efficiency.

In addition, there are many other parts in the field of automobile manufacturing that also need to use 3+2 axis CNC machining to achieve high-efficiency and high-precision manufacturing requirements. Products such as car seats and automotive electronic equipment require precise three-dimensional contours and high-quality surface processing. Through the use of 3+2-axis CNC machining, efficient and high-precision cutting of these products can be achieved to improve manufacturing quality and efficiency.

3+2 Axis CNC Machining For Electronic

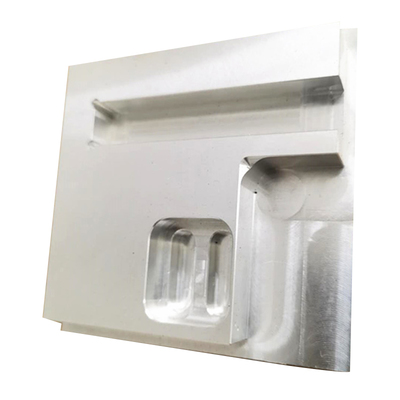

Many products in the field of electronic equipment require precise three-dimensional contours and high-quality surface processing requirements. For example, mobile phone casings require precise three-dimensional contours and high-quality surface processing, which requires high-efficiency and high-precision cutting of these products by using 3+2-axis CNC machining to improve manufacturing quality and efficiency.

In addition, there are many other parts in the field of electronic equipment that also need to use 3+2 axis CNC machining to achieve high-efficiency and high-precision manufacturing requirements, such as electronic chips, etc. These products require precise three-dimensional contours and high-quality surfaces. Through the use of 3 +2-axis CNC can improve manufacturing quality and efficiency for high-efficiency and high-precision cutting.

3+2 Axis CNC Machining For Medical Instruments

Many products in the field of medical devices require precise three-dimensional contours and high-quality surfaces. For example, artificial joints require precise three-dimensional contours and high-quality surfaces, and require 3+2-axis CNC manufacturing to improve quality and efficiency. In addition, there are many other products in the field of medical devices that require precise three-dimensional contours and high-quality surfaces plus require 3+2-axis CNC manufacturing.

As an efficient and high-precision machining method, 3+2-axis CNC machining has been widely used in various fields. With the continuous development of technology, it is believed that this processing method will be applied in more fields, bringing more breakthroughs and innovations to the development of the manufacturing industry.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

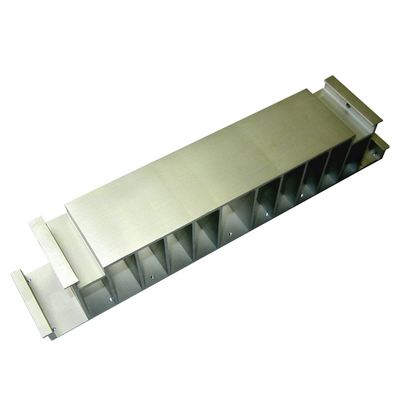

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material