-

The Selection And Design Of Manipulator Grasping Method

In the design process of the manipulator, there are many options for grabbing methods. What kind of grabbing method to choose, in addition to structural considerations, is more about the cost of use and the convenience of maintenance. Consider, after all, a good thing needs to be considered cost-effective.

2021-08-14

-

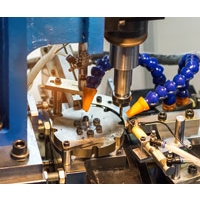

The Research On Ni-Si Alloy Slender Shaft Turning Technology

It is a difficult-to-process material and is widely used in aerospace, aviation and other fields. Its cutting is a difficult point in modern machining technology. Combining the characteristics of nickel-silicon alloy materials, taking a company's nickel-silicon alloy contacts as an example, the turning processing technology has been studied, and a certain high-temperature alloy material processing technology has been reserved for the workshop, which has certain application value.

2021-08-14

-

The Application Of AC Servo System In Shelf Cold Roll Forming Line

The introduction of the pre-punching process and hydraulic stop shear technology in the cold-formed production line of the rack column not only expands the design range and manufacturing accuracy of the cross-sectional shape of the rack column, but also meets the requirements of the design and assembly of the rack steel structure system, and optimizes

2021-08-21

-

Machining Time Selection of Crane Flange Plane

In the installation process of large crane, the flatness of crane flange will change. The conventional practice is to machine the crane flange plane after the assembly and welding of the crane base assembly, so as to ensure that the flatness of the crane flange meets the requirements of the design drawing.

2021-08-14

-

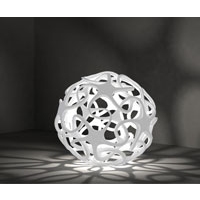

The Role Of 3D Printer In Prototype Model Making

Generally, the designed products cannot be directly mass-produced. Once they have defects, they will be scrapped, which wastes manpower, material resources and time. The prototype is the necessary step to verify the feasibility of the design in the product development process. It is a direct and effective way to find out the defects, deficiencies, and shortcomings of the designed product, so as to make targeted improvements to the defects. Common processing equipment for prototype models include CNC numerical control machine tools, 3D printers, and silicone compound mold machines.

2021-08-21

-

The Development And Application Of Thread Rolling Machining Technology

In the development and application of thread rolling machining technology, the advantages of high machining accuracy, stable quality, and high production efficiency of this technology are used in the development and application. It is considered to have high reliability in special wire machining equipment. The internal motor high-power operation makes the threaded member Play a connecting role in mechanical properties.

2020-09-18

-

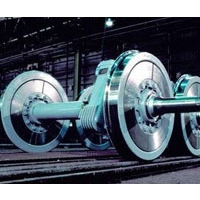

The Cnc Machining Quality Control Of Automobile Wheel Hub

Therefore, this article will combine the machining situation of automobile hubs at this stage, aiming at the factors that affect the machining quality of automobile hubs, and explore how to effectively carry out the quality control and inspection of automobile hub machining.

2021-08-14

-

The Application Of Industrial Robot Machining Loading And Unloading

This article first introduces the composition, application significance and characteristics of industrial robot machining loading and unloading applications, and detailed analysis of the rigidity and accuracy of industrial robots in industrial robot machining loading and unloading applications, as well as the rapid recovery problems after collisions and failures. The problem is analyzed in detail and the key solving techniques are analyzed. Namely, terminal load automatic identification technology and dynamic torque feedforward technology, collision detection technology, zero point recovery technology, and finally the future development trend of human-machine collaboration and information fusion is proposed.

2021-08-21

-

The Feature Extraction Method For Parts 3D Model

The premise of process design is the conversion of part information from design knowledge to process knowledge. In actual engineering, the design knowledge is included in the part 3D model and 2D drawings. In the process of conversion to process knowledge, the process designer needs to read the part 3D model and drawings. , Artificially acquire design knowledge and design corresponding processes.

2021-08-14

-

The Aerospace Parts Manufacturing Process Route Planning

The part contains several machining features, and each machining feature has several corresponding machining methods and manufacturing resources.

2021-08-21

-

The Research On Mining Decision Rules Of Part Manufacturing Process

Process decision rule mining technology aims to mine the relationship between part feature parameters, processing methods, and manufacturing resources from historical process data, and store them in the corresponding database in the form of decision rules. In the process of process design, according to the part feature parameters Match the corresponding processing methods and manufacturing resources, and push them to the craftsman for reference.

2021-08-14

-

The Current Status And Research Analysis Of CAPP Technology

Computer Aided Process Planning (Computer Aided Process Planning, CAPP) refers to the use of computer software and hardware technology and supporting environment, the use of computer numerical calculation, logical judgment and reasoning and other functions to formulate the machining process of parts. Using the CAPP system to complete relevant parameter calculations and generate process routes based on manufacturing information through human-computer interaction has an important role in reducing the labor intensity of staff, improving production efficiency, and improving product standardization.

2020-09-19

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

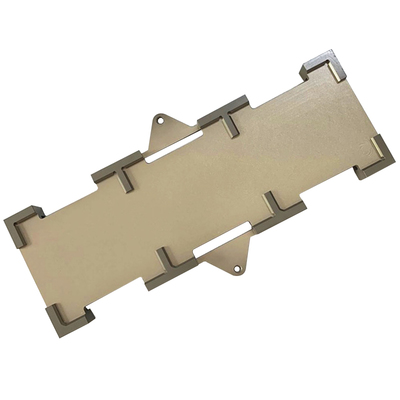

- Machinery Parts

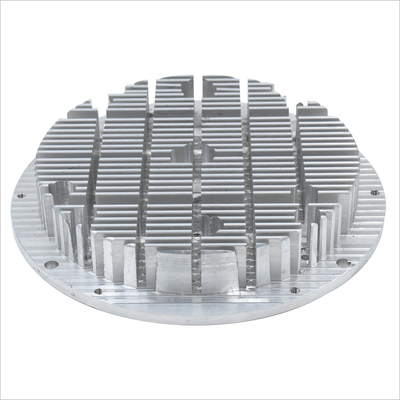

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material