-

Development and Research Status of Medical Titanium Alloys

This article delves into the development and research status of medical titanium alloys, exploring their historical evolution, current applications, and future prospects.

2024-12-15

-

TOP 5 Corrosion-Resistant Metals

This article explores five metals known for their corrosion resistance: stainless steel, titanium, aluminum, zinc, and nickel.

2024-12-23

-

What is Pre-Hardened Steel?

Pre-hardened steel refers to a category of steels that have been heat-treated to a specific hardness level prior to their final use in various applications.

2024-12-23

-

Choosing the Right Flame Retardant Plastics: A Comprehensive Guide

This comprehensive guide aims to provide a detailed overview of flame retardant plastics, their types, applications, and key considerations in choosing the right material for your needs.

2024-11-25

-

7075 Billet Aluminum vs 4140 Steel: Material Showdown

This article will explore the key properties, advantages, and disadvantages of both 7075 billet aluminum and 4140 steel, shedding light on their respective characteristics and how they compare in terms of strength, weight, machinability, corrosion resistance, and cost-effectiveness.

2024-11-11

-

Can Titanium Be Anodized?

This comprehensive guide delves into the science behind titanium anodizing, the various methods employed, its benefits, potential drawbacks, and its applications across different industries.

2024-11-23

-

What Type of Resin is Used for Gears?

This article explores the types of resins commonly used for manufacturing gears, their properties, advantages, limitations, and typical applications in various industries.

2024-11-11

-

7075 Billet Aluminum vs. 4140 Steel

This article will delve into the properties, applications, and advantages and disadvantages of both materials, providing an extensive overview suitable for engineers, manufacturers, and students of materials science.

2024-11-11

-

A Comparative Analysis of Tungsten and Titanium

This article aims to provide a comprehensive comparison of tungsten and titanium, analyzing their properties, uses, advantages, and disadvantages.

2024-10-14

-

Properties of Grade 5 Titanium

This article explores the properties of Grade 5 titanium, including its mechanical properties, corrosion resistance, thermal properties, and applications.

2024-10-14

-

The Price of Aluminum Per Pound

This article explores the various factors influencing aluminum pricing, historical trends, current market mechanisms, and future projections.

2024-09-23

-

Is Silver Magnetic?

This comprehensive analysis will provide a clear understanding of whether silver is magnetic and under what circumstances it might exhibit magnetic behavior.

2024-09-16

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

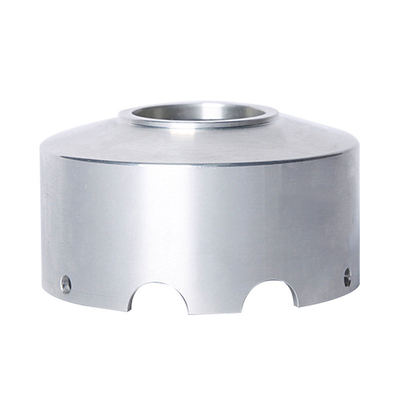

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material