Cnc Machining Price | Cnc Machining Cost Calculation

and Selecting the low prices machining service in PTJ Shop

|

In the field of CNC machining industry, machining cost evaluation is an indispensable process. Many companies have not done so well in this regard. PTJ has been in the CNC machining industry for more than 10 years. It has been exploring, innovating, and doing its utmost to provide customers with efficient and high-quality services and products. The company independently explored and developed a set of comprehensive quotation system, which to a large extent alleviated the problem of quotation with customers, promptly reported the customer's request to the customer in accordance with a reasonable and feasible process. The machining cost greatly shortens the time wasted in the quotation process. Cnc machine involves a wide range of aspects and details. Our company has absolute advantages in prototypes, plastic machining, and alloy machining. When it comes to the focus of cnc machining cost evaluation, we will give customers a satisfactory and reasonable quotation based on specific requirements and combined with the current market situation. |

|

|

|

|

|

|

|

|

|

Contact our cnc machining price machinists today to discuss the specifics of your complex parts. |

|

|

|

|

|

|

|

High Accuracy |

Quick Quote& Service |

Fast Delivery |

Custom Finishes |

Precision Machines |

Addition Services |

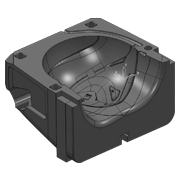

The Influencing Factors Of Machining Cost

- ▶ The precision and surface roughness of the machined parts: if the tolerance requirement of 0.001mm is required, whether the cnc machine or the technician, the requirements are relatively high, and the machining cost will be relatively high;

- ▶ The structure and size of the machined parts: If the product structure is complex, the cnc machining cost will be much higher; if the overall size of the product is large or the appearance is curved, the machining cost will also rise a lot.

- ▶ If the material to be machined is a difficult-to-process material, such as stainless steel, the material has a high hardness, and a tungsten steel hardened tool is required, and the computer gong needs to be made with Taiwan or Japanese machines, although the cost will be higher than that of ordinary materials.

In fact, customers have a relatively strong acceptance of cnc machining prices, and they really care about product quality, delivery time, and service! To this end, PTJ combines customer requirements to ensure product quality, and at the same time provides customers with some product technical suggestions, which greatly reduces customer costs, and at the same time, at the technical level, gives customers a satisfactory answer.

|

|

Contact PTJ Sales To Discuss How Much Does Cnc Machining Cost |

Cnc Machining Cost Calculation Formula

- ● Cutting Speed:Vc=(π*Dm*n)/1000

- ● OD Turning Machining Time Calculation(When The Rotating speed Is Constant:):T=(60*L)/F*n

- ● OD Turning Machining Time Calculation(When The Cutting Speed Is Constant:):T=(60*π*L*Dm)/(1000*F*VC)

- ● Machining time-outer diameter machining Part 2: When machining multiple passes(When The Rotating speed Is Constant):T=[(60*L)/(F*n)]*N

- ● Machining time-outer diameter machining Part 2: When machining multiple passes(When The Cutting Speed Is Constant):T={[60*π*L*(D1+D2)]/2*1000*F*VC}*N

- ● Machining Time - End Face Machining (When The Rotating speed Is Constant):T={[60*(D1-D2)]/2*F*n}*N

- ● Machining Time - End Face Machining (When The Cutting Speed Is Constant):T1={[60*π*(D1+D2)*(D1-D2)]/(4000*F*VC)}*N

- ● Machining Time-Grooving Machining (When The Rotating speed Is Constant):T=[60*(D1-D2)]/2*F*n

- ● Machining Time-Grooving Machining (When The Cutting Speed Is Constant):T1=[60*π*(D1+D2)*(D1-D2)]/(4000*F*VC)

- ● Machining Time-Cut Off Machining (When The Rotating speed Is Constant):T=(60*D1)/(2*F*n)

-

● Machining Time-Cut Off Machining (When The Cutting Speed Is Constant):

T1=[60*π*(D1+D3)*(D1-D3)]/(4000*F*VC)

T3=T1+(60*D3)/(2*F*n) - ● Cnc Milling Cutting speed:Vc=(π*Dc*n)/1000

- ● Table Feed And Feed Per Blade:Fz=Vf/(Z*n)

- ● Cnc Milling Machining Time:T=(60*L.)/Vf=(60*L.)/(fz*Z*n)

- ● Drilling Cutting speed:Vc=(π*Dc*n)/1000

- ● Feed(Cnc Milling Working):Vf=fz*Z*n

Cnc Machining Term Explanation

|

|